STr Production Sp. z o. o.

PRODUCTION - CNC MACHINING

Based on a modern, balanced machine park and a modernly equipped Measuring Laboratory, as well as optimized technologies, we make parts from various materials using the methods of machining, gas cutting, plasma cutting and anti-corrosion coatings.

Average order quantity

doświadczenia

We perform on average monthly

items

PRODUCTION POTENTIAL

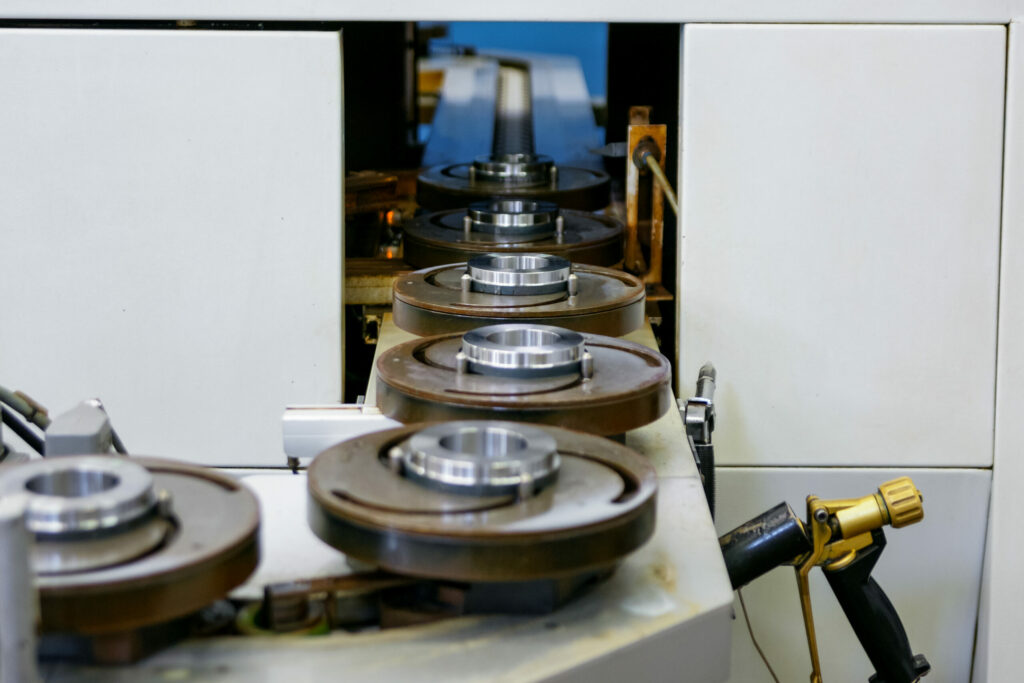

The production plant carries out its tasks on numerically controlled turning and milling centers, single and multi-torch burners, automatic band saws, drilling machines and conventional lathes.

TYPES OF PRODUCTS

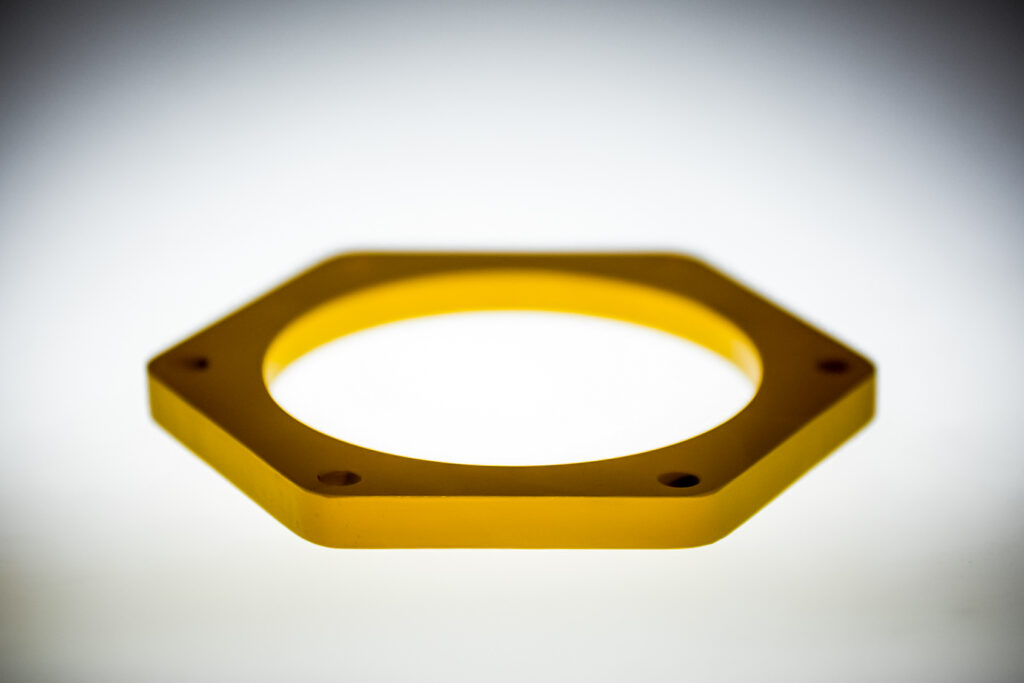

The main products offered by our company are: flanges, rings, spindles, special screws, sleeves, nuts and lids.

Currently, we produce elements using:

- Various carbon steel grades: RSt-37-2, P265GH, 13CrMo4-5, 16M03,

- stainless steel (high-alloy): 1.4301, 1.4307, 1.4541, 1.4404, 1.4571, 1.4828, 1.4462,

- bronze, brass, aluminum,

- as well Alloy and Hastelloy.

MACHINE PARK

Conventional machines enable the production of single elements with a diameter up to 900 mm.

The band saws can cut round bars up to a diameter of 440 mm.

CNC gas burners for curvilinear cutting with the effective size of material processing on the table with dimensions of 3 × 8 m, make it possible to cut black sheets up to a thickness of 90 mm. Stainless materials are cut with a Hypertherm 260 plasma machine to a maximum thickness of 40 mm (table size 2 × 6 m).

Our machine park allows us for machining of parts in the IT6 accuracy class, and in milling process in the IT10 class.

Automated production enables the implementation of medium and large series in a short time while the experience and human potential as well as the work organization system allow for quick conversion of machines and an appropriate response to customer needs.

Programming of machining machines and burners is prepared in the Technology Office and sent directly to their control systems. We prepare semi-finished products for machining according to the technology of sheet metal burning or cutting of round bars and tubes on numerically controlled band saws.

We have our own painting workshop, where carbon steel products can be protected against corrosion by using various types of protective coatings as lacquers applied by hand or machine.

The protection of the most responsible products according to customer requirements is based on the phosphating process and coating the products with special varnishes.

In cooperation with partners, we also offer electro-galvanizing, hot-dip galvanizing and epoxy coating.

At the customer’s request, stainless steel parts are washed and dried in a dedicated device.

Meet us

CONTACT

PRODUCTION DEPARTMENT

CERTIFICATES

AWARDS

STr Production Sp. z o. o.

ul. Piesza 21

70-663 Szczecin

CONTACT

Switchboard: +48 91 4623644

Fax: +48 91 4623829

E-mail: str@str.pl

© STr Production Sp. z o. o. All rights reserved